dry milling for cement process

2019-08-23T18:08:16+00:00

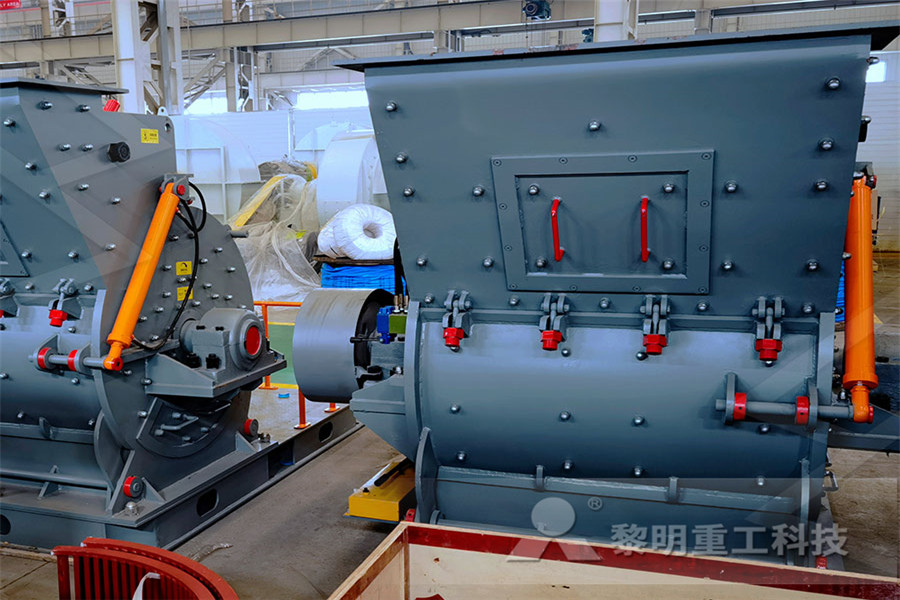

Dry Process Of Cement Manufacturing Dry Cement AGICO

The new dryprocess of cement manufacturing technology makes good use of the limestone resources discarded in the traditional mining method and applies the pre decomposition technology, suspension preheating technology, and multichannel burner Aug 25, 2020 Dry process of cement There are two methods to choose, drying and grinding the cement raw materials at the same time; or dry cement raw materials firstly, Cement Production Process Cement Manufacturing ProcessOur largest and strongest products include dry and wet milling machines that grind hard, abrasive materials for applications like mineral processing, cement plants, and power Dry milling machines Schenck Process

Concrete Milling 101 What is the concrete milling process?

Concrete milling is the process of removing the top layers of a concrete surface It’s carried out using scarifying machines equipped with diamondtipped blades Milling Jun 17, 2021 In dry milling, abrasives within the materials themselves could damage the milling equipment over time, while in wet milling, the carrier fluid used in the process, Wet Milling vs Dry Milling: The Differences, Dry milling for cement process is flourishing in China in recent years manufacture of portland cement by dry process Mining Jan 15, 2013 Manufacture of Portland Dry Milling For Cement Process caesarmachinery

Manufacturing of Cement By Dry and Wet Process

DRY PROCESS When the available raw materials are quite hard, then this process is used The cement by this process can be prepared by using the following operations: Mixing Cement milling and gypsum dehydration Because the cement gets hot due to the heat generated by grinding, gypsum can be partly dehydrated, forming hemihydrate, or plaster Cement Milling Understanding CementDry Grinding: Open circuit Ball mill, closed circuit Ball mill, vertical roller mill, Roll Press or Roll press in circuit with ball mill However, it would be seen that the most significant Raw Material DryingGrinding Cement Plant Optimization

cement drying milling process cadoasblsite

Cement Ball Mill For Dry Process thaiphysiode Cement Ball Mill For Dry Process Cement ball mill is not only suitable for overflow grinding but also applicable for cyclic Aug 15, 2020 Cement process requires fine grinding of a material blend hence recent studies have been focusing on the improvements in these applications The idea of dry stirred milling has come up with that aim and has been under investigation for many years This study aims to show the possible applications of this technology within the cement The impacts of dry stirred milling application on quality and Milling and grinding of raw material, minerals and cement is a rough process, with highly abrasive and hard feed materials that can accelerate equipment wear and tear Fast drying; Ability to handle large feed Flexible milling and grinding solutions that last

FCB Flash drying solution and FCB Aerodecantor

Our solutions can handle any type of material, whether soft or abrasive, and typically have a moisture feed of 225% FCB flash dryers are effective solutions for a fine feed size The addition of our FCB Aerodecantor in Apr 6, 2021 In dry and semi dry processes for manufacturing of cement, the raw materials are crushed and fed in the correct proportions into a grinding mill The raw matHow Cement is made? Dry process YouTubeDec 2, 2019 Size reduction is a critical process at numerous stages of cement manufacture mainly to ensure homogeneity and reactivity of the cement, raw mix, and fuels The finish mill system in cement Cement Finish Milling (Part 1: Introduction History) LinkedIn

MINERAL PROCESSING MILLING United Diversity

Rod mills are used for grinding hard minerals This type of mill is usually used as the first stage of a milling process to provide a reduced size feedstock for a further milling process Coke Products for the glass industry Cement clinker (needs to be dry) Table 5: Material Suitability for Rod MillsMay 25, 2017 On purely mechanical grounds it is difficult to see any great difference in fundamental principles between wet and dry milling, since dry milling may be regarded as wet milling with a fluid having the viscosity Dry Grinding VS Wet Grinding Mineral Processing Dry Process In the dry process of milling, the grains are ground into a powder that is hydrolyzed and transforms the sugar found in the hydrolysate to ethanol Goutham Sarang, in Use of Recycled Plastics in Ecoefficient Concrete, 2019 1432 Dry process In the dry process, aggregates are heated as in the case of normal HMAs, and then Dry Process an overview ScienceDirect Topics

What is Ball Milling Process Dry Ball Milling Process Introduce

This article takes dry ball milling as an example to introduce the ball milling process First, select the appropriate size and weight of the grinding medium according to the particle size of the grinding material The material is loaded into the cylinder by the hollow shaft at the feed end of the ball mill machineKeywords: Wet Process; Dry Process; Cement; Crushing; Milling; Nigeria 1 Introduction Cement and/or clinker (cement primary input) is a com modity being produced in over 150 countries of the world [1] It is an essential input into the production of concrete needed for building purposes and other con struction related activitiesEnergy and Cost Analysis of Cement Production Using the Oct 29, 2019 Dry process cement kiln is a kind of rotary kiln which is mainly used in calcining cement clinker The cement clinker made by the dry process has better quality and stability It can bring more economical and social benefits in production The Different Between Dry Process And Wet Process Dry ProcessWhy Choose Dry Process From Manufacturing Cement Methods

Manufacture of Portland Cement Materials and

a) Dry Process The both calcareous and argillaceous raw materials are firstly crushed in the gyratory crushers to get 25cm size pieces separately The crushed materials are again grinded to get fine particles into ball or Dry Grinding: Open circuit Ball mill, closed circuit Ball mill, vertical roller mill, Roll Press or Roll press in circuit with ball mill However, it would be seen that the most significant process and types used for raw material grinding operations in modern cement industry are: Process: Dry Closed circuit drygrinding Type of mill: Ball and Raw Material DryingGrinding Cement Plant OptimizationFeb 15, 2023 The dry milling process may be used when the particle size of powder is not very fine or when the ball milled product is to be stored or sold in powder form For example, the production of cement requires us to choose dry grinding instead of wet grinding 2 According to the overall economic perspective of ball mill grindingWhat Are the Differences between Dry and Wet Type Ball Mill?

Dry Process of Cement Manufacturing suryagoldcement

Apr 8, 2022 What is Dry Process Of Cement Manufacturing? In dry and semidry processes for cement manufacturing, the raw materials will be crushed and then fed in the correct proportions It is then added to the grinding mill Then, the raw material will be dried and reduced in size to a fine powder in thereThe cooled clinker and 3 to 5% of gypsum are crushed in the ball mill for required finegraining and then transported to the storage silo from where cement is bagged ALSO READ: DETAILED MANUFACTURING PROCESS OF CEMENT The equipment used in the dry process kiln is relatively small The process is very economicalDETAILED DRY PROCESS OF CEMENT MANUFACTURING LCETEDDry milling for cement process is flourishing in China in recent years manufacture of portland cement by dry process Mining Jan 15, 2013 Manufacture of Portland Cement By WET PROCESS The manufacture of Portland cement can be done by two methods 1 Crusher and Mill; Mining Equipment Dry Milling For Cement Process Caesarmachinery

Manufacturing of Cement By Dry and Wet Process Expert Civil

DRY PROCESS When the available raw materials are quite hard, then this process is used The cement by this process can be prepared by using the following operations: Mixing of raw materials Burning and Grinding Mixing of Raw Materials: The raw materials ie argillaceous and calcareous materials undergo the following stages:Jan 27, 2020 After the cooling process, some of the gas is used in other processes, such as coal drying, the amount of gas that needs to be cleaned can be reduced where it is mixed with gypsum and additives before Cement Manufacturing Process: 6 StepsTo Make Wet process Dry Process of Manufacture of Cement: Crushing of limestone and clay in crushers and stored in silos Grinding of crushed materials and storing in hoppers Mixing of materials by compressed air in the right proportions to form a raw mix Burning of raw mix in a rotary kiln to form clinkers2 Process Of Manufacture Of Cement Wet Process Dry Process

From Parchment To Green: The Dry Milling Process

Apr 27, 2022 As we begin the new harvest season in Peru, the Café Selva Norte dry mill prepares to process their first full harvest season for cooperatives and clients near Jaen, Peru As of September 2021, the Dry Grinding: Open circuit Ball mill, closed circuit Ball mill, vertical roller mill, Roll Press or Roll press in circuit with ball mill However, it would be seen that the most significant process and types used for raw material grinding operations in modern cement industry are: Process: Dry Closed circuit drygrinding Type of mill: Ball and Raw Material DryingGrinding Cement Plant OptimizationAug 30, 2012 Cement Manufacturing Process Phase 1: Raw Material Extraction Cement uses raw materials that cover calcium, silicon, iron and aluminum Such raw materials are limestone, clay and sand Limestone Cement Manufacturing Process Phases Flow Chart

Three Quick Tips For Manufacturing Of Cement

Oct 3, 2017 Manufacturing Of Cement by any one of the two methods : (i) Dry process, and (ii) Wet process In both these processes the three distinct operations of (a) Mixing, Ball mill (b) Burning, Rotary kiln and (c) In general, cement mill can both apply for dry cement production and wet cement production Commonly, there are three hot types of cement mill in the cement industry: cement ball mill, Raymond mill, and vertical cement mill AGICO Cement can supply cement mill according to your requirementsCement Mill Cement Ball Mill Vertical Cement Mill AGICOAug 15, 2020 The simulation studies concluded that the use of dry stirred mill in cement grinding process led to a reduction in energy utilization and an increase in the production rate However, the technology being utilized for a given process is decided after a thorough economic evaluation including the costs associated with the maintenance as wellThe impacts of dry stirred milling application on quality and

The cement kiln Understanding Cement

This reduces the capital costs of a new cement plant A dry process kiln might be only 70m long and 6m wide but produce a similar quantity of clinker (usually measured in tonnes per day) as a wet process kiln of the same diameter but 200m in length The milling process generates heat and excessive mill temperatures are undesirable It is Apr 4, 2013 Dry ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building ball mill manufacturer,ball mill suppliers We are China's most professional ball mill manufacturer, dry ball milling process Mining Quarry Plant