grinding iron ore pellets

2022-01-03T00:01:52+00:00

Iron Ore Pellet an overview ScienceDirect Topics

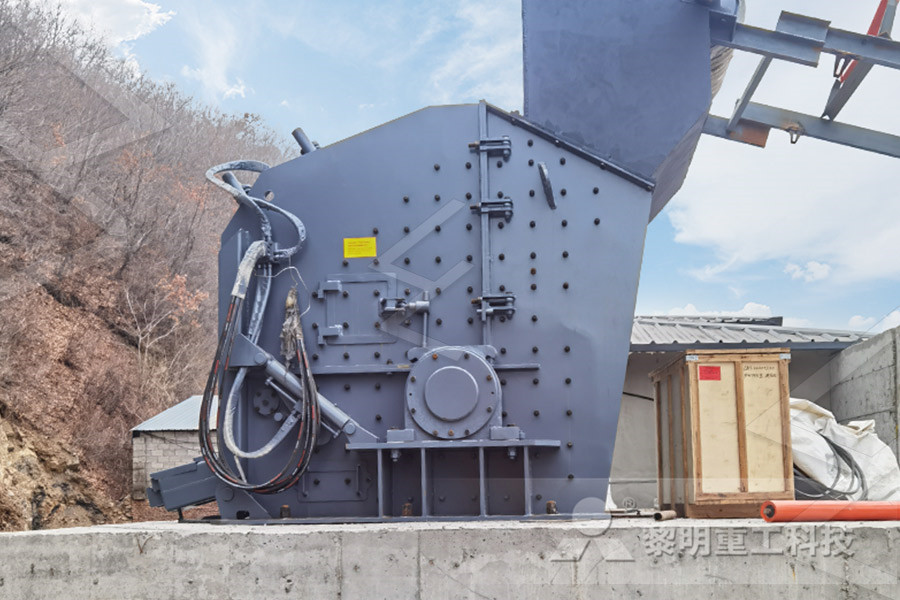

Raw material for pellets is produced by crushing and grinding lowgrade iron ores—typically of the taconite class and finer than 325 mesh (0044 mm)—and Jul 11, 2018 The iron ore pelletizing process consists of three main steps: Pelletizing feed preparation and mixing: Iron Ore Pelletizing Process: An OverviewMar 15, 2015 To assess the feasibility of HPGR dry grinding for generating a fine iron ore pellet feed a series of studies is being Concluding remarks HPGR is a feasible size Pellet feed grinding by HPGR ScienceDirect

Iron Ore Pelletization FEECO International Inc

Iron ore must go through a lengthy preprocessing stage before it can be pelletized – a series of steps that work to beneficiate and concentrate lowgrade ores This process Feb 23, 2013 Pelletizing is a process which involves mixing of very finely ground particles of iron ore fines having a size which is less than 200 mesh (0074 mm) with additives Introduction to Iron ore Pellets and Jun 11, 2019 Seven openpit iron ore mines (each with associated concentration and pelletizing plants), and three iron metallic plants—one directreduced iron (DRI) plant Sintering: A Step Between Mining Iron Ore

DRGrade Iron Ore Pellets A Supply

Blast furnace pellets made up 55% of sales value and DR pellets accounted for 26% According to iron ore trade statistics, Sweden exported about 7 million tons of DR Oct 18, 2020 The effects of iron ore concentrate grinding methods (HPGR and Ball mill) on green pellet properties a pilot plant case study Authors: Seyed Hamzeh Amiri M The effects of iron ore concentrate grinding methods Jan 1, 2022 Iron ore pellets are essential burden materials to improve the performance of modern blast furnaces, because they possess high iron grade, low silica and alumina contents, excellent mechanical strength and metallurgical Iron ore pelletization ScienceDirect

Pelletization Outotec

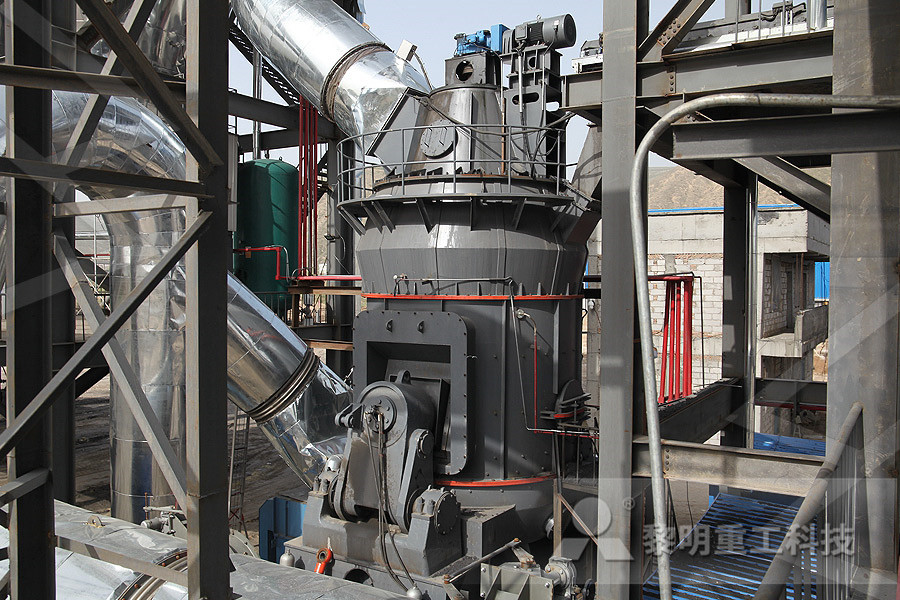

Pelletization Boosting production capacity Parts and services Pelletization is the process of transforming iron ore fines into spherical pellets through agglomeration and induration These pellets are then used as feed to a blast furnace Iron ore must go through a lengthy preprocessing stage before it can be pelletized – a series of steps that work to beneficiate and concentrate lowgrade ores This process varies depending on the ore source, but typically involves various stages of crushing and grinding to reduce the size of the iron oreIron Ore Pelletization FEECO International IncMar 19, 2022 An iron ore concentrate sample was ground separately in a pilotscale HPGR mill in multiple passes and a dry opencircuit ball mill to increase the specific surface area of particles The effects of grinding mechanisms on generating pellet feed were assessed and pellets and DRIs were producedGrinding iron ore concentrate by using HPGR and ball mills and

Development of a Novel Grinding Process to Iron Ore Pelletizing

Mar 28, 2020 DOI: 101007/s4246102000202z Corpus ID: ; Development of a Novel Grinding Process to Iron Ore Pelletizing through HPGR Milling in Closed Circuit @article{Thomazini2020DevelopmentOA, title={Development of a Novel Grinding Process to Iron Ore Pelletizing through HPGR Milling in Closed Circuit}, author={Anderson Aug 25, 2020 Brazil’s Vale (NYSE: VALE) has begun producing highgrade iron ore fines for pelletizing at its new threemilliontonnesayear grinding hub at China’s Vale opens iron ore grinding hub in ChinaJun 11, 2019 According to the US Environmental Protection Agency, the sintering process converts finesized raw materials, including iron ore, coke breeze, limestone, Sintering: A Step Between Mining Iron

Process flow sheet for Pelletization using

The pelletizing process has now been completed The pellets are run through a final screening to remove those not meeting size specifications or those that are chipped or Mar 28, 2020 212 Ore Blend Grinding at HPGR and Ball Mill The ore blend was ground in a pilotscale HPGR (1 m diameter × 032 m width) at a maximum feed rate of 50 t/h The ground product was recirculated to the HPGR feeding hopper five or seven times, wherein every recirculation steps a sample was gathered for moisture and size distribution Development of a Novel Grinding Process to Iron Ore Pelletizing of the processed ore shipped to the iron and steel industry is in the form of pellets Other forms of processed ore include sinter and briquettes The average iron content of pellets is 63 percent 11232 Process Description25,41 Processing of taconite consists of crushing and grinding the ore to liberate ironbearing particles,1123 Taconite Ore Processing US EPA

Pressing iron ore concentrate in a pilotscale HPGR Part 1

Aug 15, 2019 The present work studied the performance of a pilotscale HPGR pressing an iron ore concentrate under a variety of conditions that are consistent with pregrinding As already observed by Van der Meer and Leite (2018) for iron ore pellet feed pressing and confirmed here, specific throughput tends to drop as the operating pressure is increased Jan 1, 2015 Iron ore pellets are essential burden materials to improve the performance of modern blast furnaces, because they possess high iron grade, low silica and alumina contents, excellent mechanical strength, and metallurgical performance with a uniform size distribution (Secondary Grinding of Pellet Feed of Iron Ores Due to Mineralogy Iron ore pelletization ScienceDirectMar 28, 2020 The grinding tests were performed feeding a blend of 80% ore A (compact and harder) and 20% ore B (porous and brittle) The variable parameters evaluated were mixture moisture, product recirculation steps into the HPGR (without classification), feed moisture at HPGR, and bentonite dosageDevelopment of a Novel Grinding Process to Iron Ore Pelletizing

Grinding iron ore concentrate by using HPGR and ball mills and

Mar 19, 2022 An iron ore concentrate sample was ground separately in a pilotscale HPGR mill in multiple passes and a dry opencircuit ball mill to increase the specific surface area of particles The effects of grinding mechanisms on generating pellet feed were assessed and pellets and DRIs were producedAug 25, 2020 Brazil’s Vale (NYSE: VALE) has begun producing highgrade iron ore fines for pelletizing at its new threemilliontonnesayear grinding hub at China’s Shulanghu Ore Transfer Terminal Vale opens iron ore grinding hub in ChinaJun 11, 2019 According to the US Environmental Protection Agency, the sintering process converts finesized raw materials, including iron ore, coke breeze, limestone, mill scale, and flue dust, into an Sintering: A Step Between Mining Iron Ore and

Development of a Novel Grinding Process to Iron Ore Pelletizing

Mar 28, 2020 DOI: 101007/s4246102000202z Corpus ID: ; Development of a Novel Grinding Process to Iron Ore Pelletizing through HPGR Milling in Closed Circuit @article{Thomazini2020DevelopmentOA, title={Development of a Novel Grinding Process to Iron Ore Pelletizing through HPGR Milling in Closed Circuit}, author={Anderson Oct 18, 2020 The effects of iron ore concentrate grinding methods (HPGR and Ball mill) on green pellet properties a pilot plant case study Authors: Seyed Hamzeh Amiri M Izadi YazdanAbadi MThe effects of iron ore concentrate grinding methods (HPGR and The iron ore pellet market is expected to achieve stable growth from 2021 to 2028 According to the analysis of Data Bridge Market Research, the market is growing at a CAGR of 36% The iron ore Iron Ore Pelletizing Plant Iron Ore Pelletizing

CSB2 Iron ore pellets and method of manufacturing

7 grinding Methods 0000 description 8; CPLXHLVBOLITMKUHFFFAOYSAN magnesium oxide Chemical compound [Mg] Fired ironore pellets having at least two different precipitated slag phases and process for producing the same USA (en) : Iron ore reduction Dec 1, 2022 The physical properties of iron ore concentrate, such as the morphology of particles, specific surface area, and particle size distribution, have a significant effect on the quality of green pellets , , The grinding method and its associated parameters strongly affect the physical properties of the iron ore concentrateMechanism of magnetite iron ore concentrate morphology