feeding device ball mill

2021-08-06T16:08:29+00:00

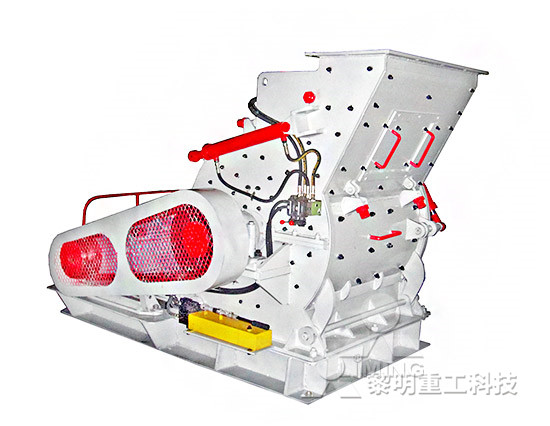

Optimization Of Ball Mill Feeding Device Design ball mills

Ball Mill DesignOptimization Of Feeding Device Design of BallnormalMill Feeding Method Whether the design of the feeding device is reasonable or not, determines the operation Outotec's ball feeding technology utilizes a simple and robust design to continously and efficiently feed the grinding mill With this in place, the grinding mill can operate at Ball feeder OutotecJan 1, 2021 Ball mill is a kind of raw material processing machinery which plays the role of grinding Its working principle is that the movement and force are transmitted to the (PDF) Design of Threechamber Ball Mill ResearchGate

PERI™ AutoCharge Mill Grinding Ball Charging System

Our PERI AutoCharge Mill Grinding Ball Charging System is designed to provide a controlled continuous supply of balls to maintain consistent ball loading in the grinding Aug 14, 2019 Ball mill is a common grinding equipment in concentrator, the main role is to provide qualified grinding products for the subsequent dressing process The ball The Ultimate Guide to Ball Mills Dec 1, 2020 The work is dedicated to the engineering and 3D modeling of an automated device for feeding balls to the mill in the MMPs mill drum The new device will reduce Creating a project for modernizing the feeding balls

Ball Mills Mineral Processing Metallurgy

Feb 13, 2017 Types of Mill Feed Chute Scoop Feeders for BallRod Mills are made in various radius sizes Standard scoops are made of cast iron and for the 3′ size a 13″ or 19″ feeder is supplied, for the 4′ The working principle of ball mill The material enters the first chamber of the mill evenly and spirally from the feeding device through the feeding hollow shaft There are Ball Mill Ultrafine Powder TechnologyThe utility model discloses a feeding device of an aluminum powder ball mill, which comprises: the grinding machine is arranged at the output end of the feeding pipe, and a CNU Feeding device of aluminum powder

Ball mill Wikipedia

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering It works on the principle of impact and Ball Mill DesignOptimization Of Feeding Device Design of BallnormalMill Feeding Method Whether the design of the feeding device is reasonable or not, determines the operation of the ball mill feeding system, which directly affects the actual output of the ball mill There are generally two types of feeds designed for traditional ball mills: 1Optimization Of Ball Mill Feeding Device Design ball mills Outotec's ball feeding technology utilizes a simple and robust design to continously and efficiently feed the grinding mill With this in place, the grinding mill can operate at maximum productivity levels compared to those mills without a grinding media feeding system Select™ ball feeders are designed for all applications using steel Ball feeder Outotec

PERI™ AutoCharge Mill Grinding Ball Charging System

Our PERI AutoCharge Mill Grinding Ball Charging System is designed to provide a controlled continuous supply of balls to maintain consistent ball loading in the grinding mill Continuously charging grinding balls will allow your mill to maintain a consistent power draft, charge volume, ore feed rate, or consumption average (kg/t)Dry and wet ball mills have the same basic components, but there are some structural differences: 1 Partition The dry ball mill is doublewall or three partitions The wet ball mill is singlewall partition 2 Feeding device Dry ball mill: drum feeder, feed hopper, combined feeder Wet ball mill: feed hopper, combined feederBALL MILL FOR ALL YOUR NEEDS ftmmachineryFeb 13, 2017 A ball mill efficiently operated performs a wide variety of services In small milling plants, where simplicity is most essential, it is not economical to use more than single stage crushing, because the Steel Ball Mills Mineral Processing Metallurgy

Ball Mill And Air Classifier Production System EPIC Powder

Product Feature 01 With Al2O3 or silex or steel liningMainly designed with overflow type or grate discharge wall 02 With air through the mill or with airswept principle to get cooler and take out ground material 03 Inlet chute for ball mill includes accessory for feeding grinding aid directly into the mill drum 04This article takes dry ball milling as an example to introduce the ball milling process First, select the appropriate size and weight of the grinding medium according to the particle size of the grinding material The material is loaded into the cylinder by the hollow shaft at the feed end of the ball mill machineWhat is Ball Milling Process? ball mills supplierThe utility model discloses a feeding device of an aluminum powder ball mill, which comprises: the grinding machine is arranged at the output end of the feeding pipe, and a feeding hopper is fixed at the input end of the feeding pipe; and the dustproof box is fixed on the surface of the feed hopper, a connecting pipe is embedded in the upper end face CNU Feeding device of aluminum powder ball mill

Ball mill Wikipedia

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering It works on the principle of impact and attrition: size The invention relates to a feeding circulation combined sealing device of a wet type ball mill, which is applied to a powder milling system in the industries of metal and nonmetal mines, chemical industries, construction materials and the like The sealing structure comprises a water return ring, a mill feeding bush, a radial rubber scraping plate, an Feeding circulation combined sealing device of wet type ball millThe ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ball coating, or Ball Mill an overview ScienceDirect Topics

Ball millBAILING® Machinery

The ball mill made by the Chinese ball grinder manufacturer is a grid shaped one made up of a horizontal type cylinder rotating device, gear drive and two cabins There are two grinding modes: wet type and dry type The discharging ways can be divided to grid type and over flow type Ball mills are in many shapes: short drum one, long drum one Ball Mill DesignOptimization Of Feeding Device Design of BallnormalMill Feeding Method Whether the design of the feeding device is reasonable or not, determines the operation of the ball mill feeding system, which directly affects the actual output of the ball mill There are generally two types of feeds designed for traditional ball mills: 1Optimization Of Ball Mill Feeding Device Design ball mills Outotec's ball feeding technology utilizes a simple and robust design to continously and efficiently feed the grinding mill With this in place, the grinding mill can operate at maximum productivity levels compared to those mills without a Ball feeder Outotec

BALL MILL FOR ALL YOUR NEEDS ftmmachinery

Dry and wet ball mills have the same basic components, but there are some structural differences: 1 Partition The dry ball mill is doublewall or three partitions The wet ball mill is singlewall partition 2 Feeding device Dry ball mill: drum feeder, feed hopper, combined feeder Wet ball mill: feed hopper, combined feederRETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest Ball Mill RETSCH powerful grinding and homogenizationProduct Feature 01 With Al2O3 or silex or steel liningMainly designed with overflow type or grate discharge wall 02 With air through the mill or with airswept principle to get cooler and take out ground material 03 Inlet chute for ball mill includes accessory for feeding grinding aid directly into the mill drum 04Ball Mill And Air Classifier Production System EPIC Powder

CNU Feeding sealing device of wet type ball mill

Sep 10, 2010 The utility model discloses a feeding sealing device of a wet type ball mill, belonging to the technical field of ball mills and comprising a feeding chute of the mill, a sealingCylindrical energy saving grid ball mill design consist of feeding part, discharging part, rotary part, transmission part (reducer, small gear, motors, electrical control) and other major parts Hollow shaft is steel castings, and the liner is detachable Rotary gear is processed by casting hobbingHow does a ball mill work? QuoraBall mill is widely used in mining, smelting,road,building material and chemical It is the key equipment for grinding after the crush processThe mill consists of feeding device, driving assembly, rotating assembly,bearing unit,discharging assembly and foundation unitIt is a high technological enterprise that integrated research , manufacture, sales and service Dry ball mills Jinpeng Mining

Roller mills: Precisely reducing particle size with greater

More about the feeding device The feeding device is integral to the roller mill Common feeding devices include rotary feeders (for granular feed with an average particle size from 1⁄ 4 to 3⁄ 4 inch) and vibratory feeders (for powder feed with an average size up to about 400 microns) To provide a constant feedrate, the feeding device May 8, 2021 Vibratory feeders are used in gravimetric feeding systems to handle solids with particles that are loo large to be handled by screw, rotaryvane, or verticalgate VIBRATING FEEDER 911MetallurgistThe invention relates to a feeding circulation combined sealing device of a wet type ball mill, which is applied to a powder milling system in the industries of metal and nonmetal mines, chemical industries, construction materials and the like The sealing structure comprises a water return ring, a mill feeding bush, a radial rubber scraping plate, an Feeding circulation combined sealing device of wet type ball mill

Emax High Energy Ball Mill Retsch

The Emax is an entirely new type of ball mill for high energy milling The unique combination of high friction and impact results in extremely fine particles within the shortest amount of time faster and finer grinding than any other ball mill speed of 2000 min 1 allow for ultrafast pulverization of the sample