ball mills centrifugal

2021-10-18T14:10:14+00:00

Centrifugal ball mills Baan Machines

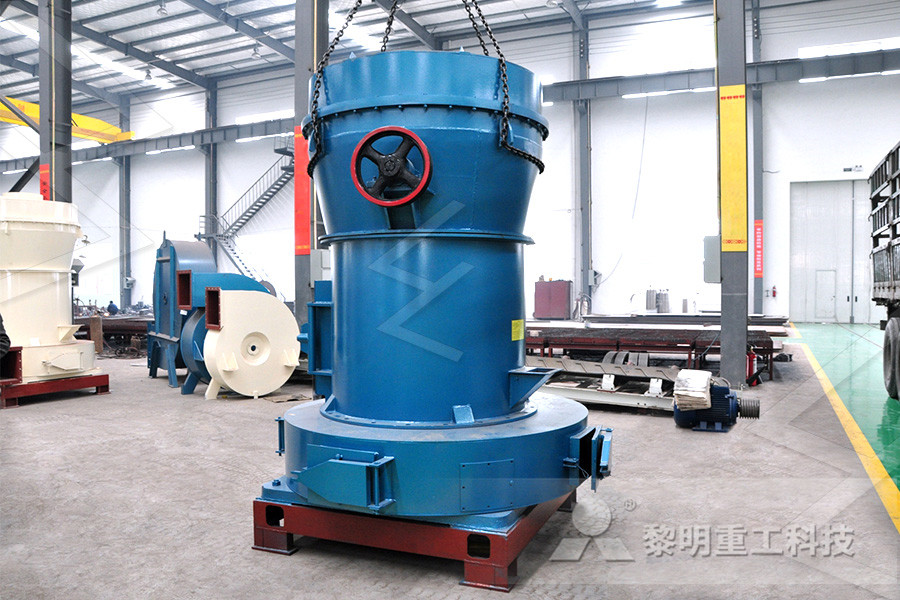

15 rows Centrifugal differ in some ways from Planetary Mills We have them available for two sizes of jars 300ml and 1000ml Primarily meant for laboratory use, these mills are also suitable for grinding small batches of Centrifugal ballmills according to the present invention can be of any desired size from smallscale laboratory models and up to very large ones for use in industry, for size USA Centrifugal ball mill Google PatentsA centrifugal ball mill has a cylindrical container in which an object to be crushed and a crushing ball are contained, a revolution mechanism that revolves the container about a USA1 Centrifugal ball mill Google Patents

Ball Mill an overview ScienceDirect Topics

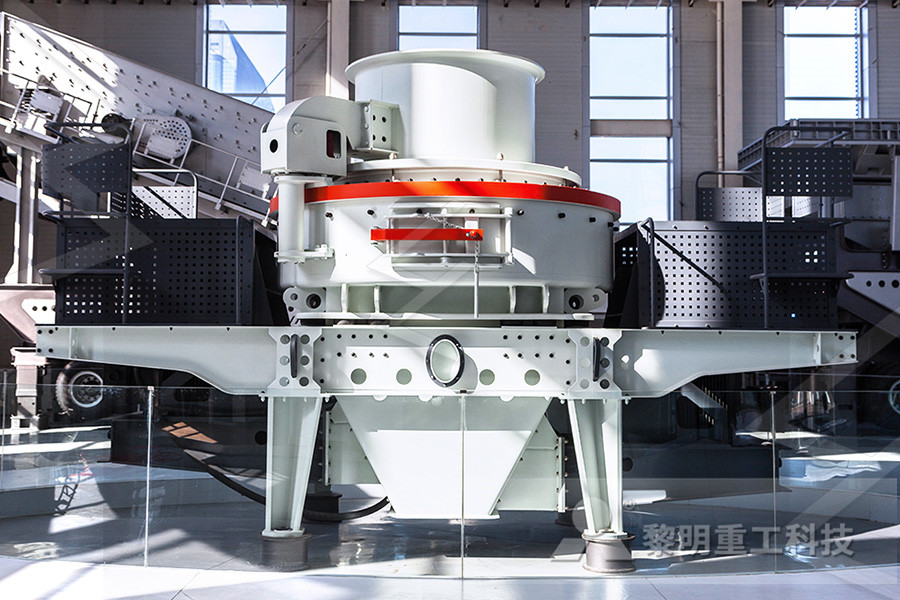

A ball mill is a type of grinder used to grind and blend bulk material into QDs /nanosize using different sized balls The working principle is simple; impact and attrition size As the ball mill rotates, the balls ‘stick’ to the inner surface of the drum due to the centrifugal force created within the drum At a certain angle, the weight of the balls overcomes the centrifugal force holding them against Ball Mill Explained saVReeThe extremely high centrifugal forces of planetary ball mills result in very high pulverization energy and therefore short grinding times The PM 400 is a robust floor model with 4 Planetary Ball Mills Glen Mills, Inc

Planetary Ball Mill 911Metallurgist

The centrifugal forces created by the rotation of the Mechanical Alloying A short milling duration of only 30 to 60 min In cases where relatively high temperature is necessary to promote reaction rate, even this may be an Jun 12, 2016 Ball mills, also known as centrifugal or planetary mills, are devices used to rapidly grind materials to colloidal fineness (approximately 1 micron and below) by developing high grinding energy via centrifugal The Glassware Gallery: Ball Milling ilpiA Giant Inflatable Fun Park Bounce, slide and dance your way through a surreal, candycolored wonderland featuring the largest ball pit on the planet, a 600ft long obstacle Bounce The Mall

USA1 Centrifugal ball mill Google Patents

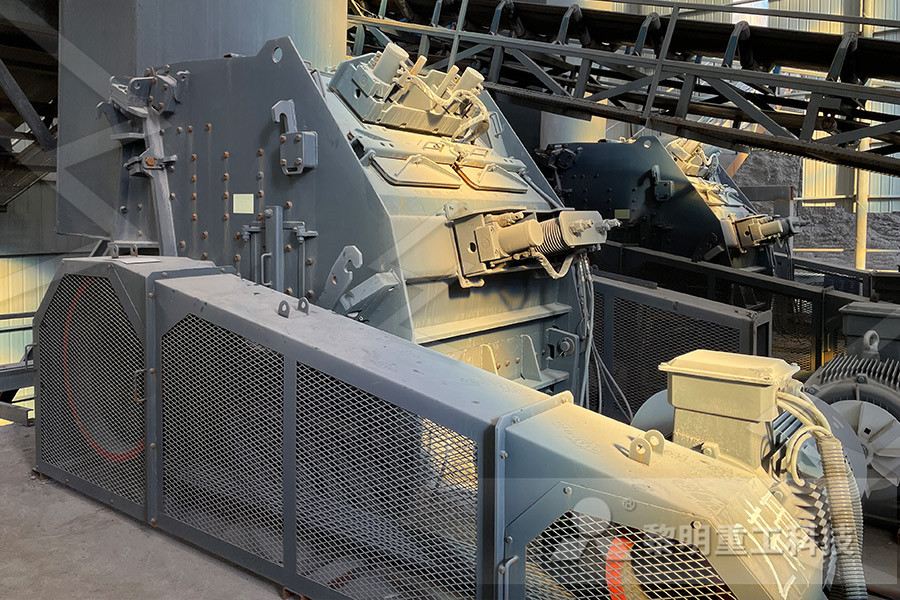

A centrifugal ball mill has a cylindrical container in which an object to be crushed and a crushing ball are contained, a revolution mechanism that revolves the container about a revolution axis, and a rotation mechanism that rotates the container about a rotation axis Furthermore, the centrifugal ball mill has an inclination mechanism that inclines an A centrifugal mill is provided to move smoothly raw materials and milling media by positioning an inlet port higher than an outlet port and to utilize milling media of various sizes and specific gravity by separating the milling media from the raw materials by centrifugal force of a rotary chamber A centrifugal mill for receiving powdered or liquid raw KRB1 A ball mill using the centrifugal force Google Ball mills, also known as centrifugal or planetary mills, are devices used to rapidly grind materials to colloidal fineness (approximately 1 micron and centrifugal grinder stamp ball mills Crusher News Find ★ centrifugal grinder stamp ball mills ★ on the web ? Welcome to the Shanghai liming Mining and Construction Machinery Co, LtdCentrifugal Ball Mill Crusher Mills, Cone Crusher, Jaw Crushers

Ball Mills Mineral Processing Metallurgy

Feb 13, 2017 SteelHead BallRod Mills are available in any one of five different types of discharge: Overflow, perforated overflow, return spiral, grate, and peripheral The extremely high centrifugal forces of planetary ball mills result in very high pulverization energy and therefore short grinding times The PM 400 is a robust floor model with 4 grinding stations You may also be interested in the High Energy Ball Mill Emax, an entirely new type of mill for high energy input The unique combination of high Planetary Ball Mills Glen Mills, IncJun 19, 2015 A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell’s inside surface and no balls will fall from its position onto the shell The imagery below helps explain what goes on inside a mill as speed varies Use our online formulaBall Mill Critical Speed Mineral Processing Metallurgy

The ball mill Chemical Engineering Beyond Discovery

Feb 19, 2023 The ball mill is used for the grinding of a wide range of materials, including coal, pigments, and felspar for pottery, and it copes with feed up to about 50 mm in size The efficiency of grinding increases with the holdup in the mill, until the voids between the balls are filled Further increase in the quantity then lowers the efficiencyPlanetary Ball Mills are used wherever the highest degree of fineness is required In addition to wellproven mixing and size reduction processes, these mills also meet all PM 100 Planetary Ball Mill Glen Mills, IncManufacturer: Vega Art 02 Ball mill with silica lining Second hand machine Silica pebbles Drum ext dimensions ø 1600 x L 1550 mm Belt transmission with hydrodynamic joint Electric motor power 7,5 Hp Indicative cUsed Vega Ball Mills for sale Machinio

Microfine comminution in a new centrifugal ball mill ostigov

Dec 31, 1995 The US Department of Energy's Office of Scientific and Technical InformationBall milling is a mechanical technique that is broadly used to grind powders into fine particles [134–141] The reactants are generally broken apart using solvent molecules in the traditional method; but in ball milling, reactants are broken by using mechanical forces The term mechanochemistry has been introduced very recently [142]Ball Milling an overview ScienceDirect TopicsCentrifugal Millrapid size reduction of soft to mediumhard and fibrous materials Size reduction principleimpact, shearing Feed size10mm Final fineness 40μm Motor speed6000 – 18000 rpm, constant adjustable Peripheral speed314~942m/s Rotor diameter98mm Collecting pan volume900ml (volume of the sample collected no more than 300m Power Centrifugal Mill MRCLab

Centrifugal ball mill BLOCH; RUDOLF MOSHE

In such a ballmill centrifugal forces are used, and a substantial improvement in performance of the mill can be achieved The planetary movement is actuated by means of transmission belts or piston arrangements A ballmill of this type has been described by R Bloch and C Rosetti in Chemiker Zeitung (1932), page 196 Due to the utilization Jun 29, 2022 Ball mill is a grinder for reducing hard materials to powder The grinding is carried out by the pounding and rolling of a charge of steel or ceramic balls carried within the cylinder Type of ball mills, centrifugal and planetary mills, are devices used to rapidly grind materials to colloidal fineness (approximately 1 μm and below) by Ball mill @ Chemistry Dictionary GlossaryPlanetary Ball Mills are used wherever the highest degree of fineness is required In addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding PM 100 Planetary Ball Mill Glen Mills, Inc

Emax High Energy Ball Mill Retsch

The High Energy Ball Mill Emax combines highfrequency impact, intensive friction, and controlled circular jar movements to a unique and highly effective size reduction mechanism Emax Function Features Under the centrifugal accelerations applied by the machine, the grinding ball or balls shoot back and forth within the jar This leads not only to high impact forces but also to an additional high shear force not present in SpeedMixer™ High Energy Grinding Mill l FormTech Ball mills and agitated media mills work according to a simple principle The balls are freely movable grinding media in a vertical or horizontal drum as centrifugal force would then hold the balls against the drum wall, also preventing the product being ground For you, this means that it is important to find the right speed range to Ball Mills Agitated Media Mills Hosokawa Alpine

Emax High Energy Ball Mill Glen Mills, Inc

Product Advantages Faster and finer grinding than any other ball mill Speed of 2000 min1 allow for ultrafast pulverization of the sample Water cooling permits continuous operation without cool down breaks Centrifugal differ in some ways from Planetary Mills We have them available for two sizes of jars 300ml and 1000ml Primarily meant for laboratory use, these mills are also suitable for grinding small batches of Centrifugal ball mills Baan MachinesAug 11, 2017 In the planetary ball mill, centrifugal and Coriolis forces permit grindings down to the submicron range The result of grinding of alumina (Al 2 O 3) at 650 min 1 in the PM 100 is shown in Figure 5Laboratory Ball Mills for Ultrafine Grinding AZoM

Grinding Down to the Nanoscale with Planetary Ball

Apr 3, 2013 Planetary ball mills are the most commonly used ball mills in laboratories for preparing samples ranging from soft to hard to brittle and fibrous materials The mill derives its name from the unique kinematics in a tumbling ball mill and about 50 times greater than that in a stirred ball mill2) Another result is given in Fig 3, from which it is seen that even small glass beads with a low density can be used to grind hard materials such as silica sand in the planetary ball mill be cause of the great centrifugal accelerationThe Mechanism and Grinding Limit of Planetary Ball Oct 11, 2015 In the planetary ball mill, centrifugal and Coriolis forces permit grindings down to the submicron range The calciner discharge of TiO2 white pigments from the sulphate process is ground (PDF) Ultrafine Grinding with Laboratory Ball Mills

The ball mill Chemical Engineering Beyond Discovery

Feb 19, 2023 The ball mill is used for the grinding of a wide range of materials, including coal, pigments, and felspar for pottery, and it copes with feed up to about 50 mm in size The efficiency of grinding increases with the holdup in the mill, until the voids between the balls are filled Further increase in the quantity then lowers the efficiencyAug 10, 2020 Ball mills are a special instrument used to break up hard solids into a fine powder They are similar to rock tumblers in that the How to Make a Ball Mill: 12 Steps (with Pictures)Jul 7, 2017 This condition is reached at about 60 to 80 percent of the critical speed of the mill where the centrifugal force is high enough to prevent the media from completely falling back down on the material bed Ball mill configuration Ball mills use shear and impact milling techniques Ball milling uses shear forces when particles are stressed Top 5 productspecific milling technologies used in industrial

Ball milling: a green technology for the preparation and

The ball mill Ball milling is a These were milled together with PHBV using a centrifugal ball mill at 650 rpm for 60 minutes The resulting composites were then moulded in a hot press to form thick films The dispersion of the s within the polymer matrix was studied by SEM, which showed a good dispersion and distribution of the crystals