jaw crusher material

2020-07-23T04:07:07+00:00

Jaw Crushers McLanahan

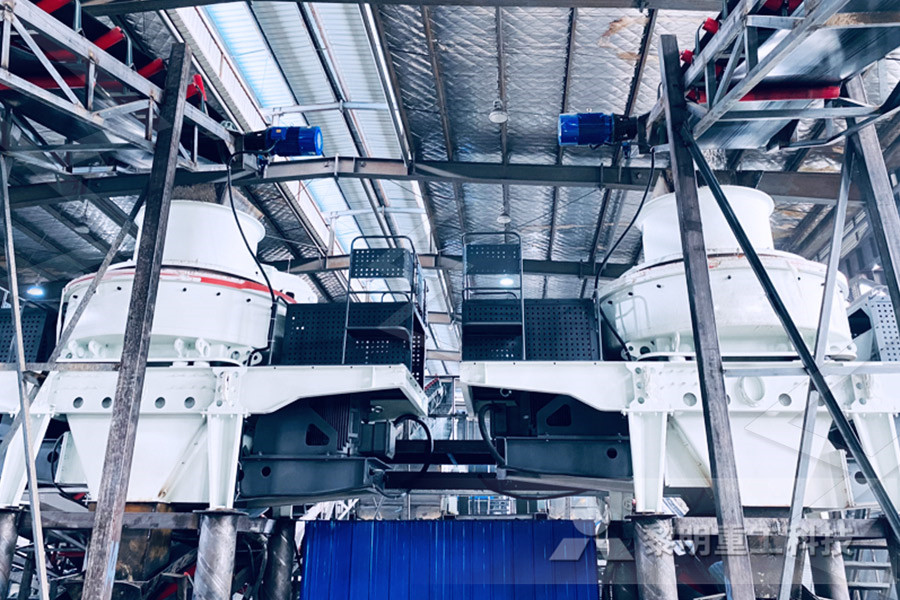

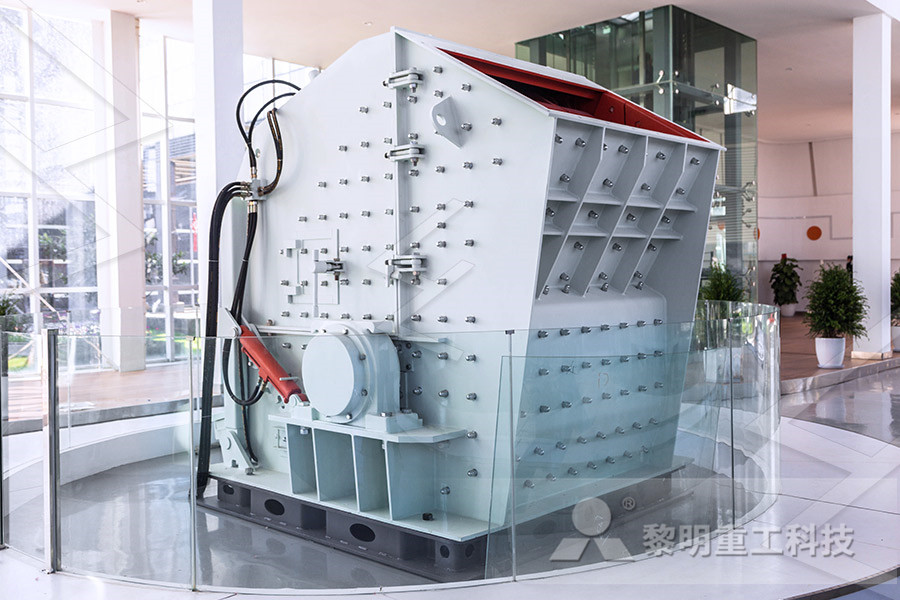

Jaw Crushers are a compressiontype machine that crush material between a moving piece of steel and a stationary piece of steel They are used for primary and sometimes secondary size reduction Applications Aggregates CD Recycling Concrete Crushing The capacity of a jaw crusher is given by the amount of crushed material passing the discharge opening per unit time This is dependent on the area of the discharge opening, Jaw Crusher an overview ScienceDirect TopicsMar 25, 2019 There is some material for jaw crusher plate: High Manganese Steel This high manganese grade is an excellent work hardening, abrasion resistant steel This steel is a nonmagnetic Jaw Crusher Plate Material MGS Casting

Jaw Crushers

Jaw Crushers jaw crushers are designed to exceed the primary crushing needs of customers in the mining, quarrying, and recycling industries These crushers Feb 18, 2021 A jaw crusher essentially crushes large rocks to a more usable size They’re typically the firstline machinery used in the material reduction for several applications This includes rock quarries, sand and What Is a Jaw Crusher? Here's How It Works Cutting The structure of the jaw crusher is mainly composed of a movable Jaw Crusher Plates, a fixed jaw plate and an eccentric shaft When the eccentric shaft rotates, the movable jaw plate mainly bears the What are the Materials of the Jaw Crusher Plates and

What is the best material for crusher jaw plates?

Dec 23, 2020 Alloy Steel Jaw Plates This material is developed by Qiming Machinery We use alloy steel to cast small jaw crusher jaw plates Normally, the weight of alloy steel Outotec jaw crusher wear parts are made of highquality manganese in a continuously monitored process at our own foundries and manufacturing facilities Keep control of your operation with OSeries jaw Jaw crusher parts OutotecMar 8, 2023 Fine materials should not enter a jaw crusher because they tend to cause damage to the machine over time due to the small size and abrasive nature of the Why fine material should not enter a jaw crusher?

Estimate Jaw Crusher Capacity Mineral Processing

Feb 17, 2016 jaw crusher production capacity Example capacity calculation of a 10″ x 20″ (250 mm x 500 mm): Pp = 2800 (28 SG) e = 02 (halfway between dolomite and sandstone) A = 250/1000 x 500/1000 Wj Sandvik jaw crushers are reliable, highperforming crushers built to optimize primary crushing applications in mines and quarries These tough crushers are delivered with everything you need for plugandplay Jaw crushers, Stationary Jaw crusher series — SRP® C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up to 11,000 jaw crusher installations since 1975 Developed to crush the hardest ores and rocks, jaw crushers also perform outstandingly with less demanding materials® C Series™ jaw crushers Proven reliability and

Jaw Crushers MEKA Crushing Screening Plants

Jaw crushers are one of the most commonly preferred crushers due to their ability to crush all kinds of materials of any hardness, as well as their lowcost operation and easy maintenance “Crusher performance Engineered to be the highestcapacity jaw crusher on the market, the Pioneer ® Jaw Crusher will deliver up to 25 percent more tons per hour than comparable jaw crushersPioneer® Jaw Crushers AstecFeb 18, 2021 A jaw crusher essentially crushes large rocks to a more usable size They’re typically the firstline machinery used in the material reduction for several applications This includes rock quarries, sand and What Is a Jaw Crusher? Here's How It Works

Jaw Crusher Premiertrak 400X R400X

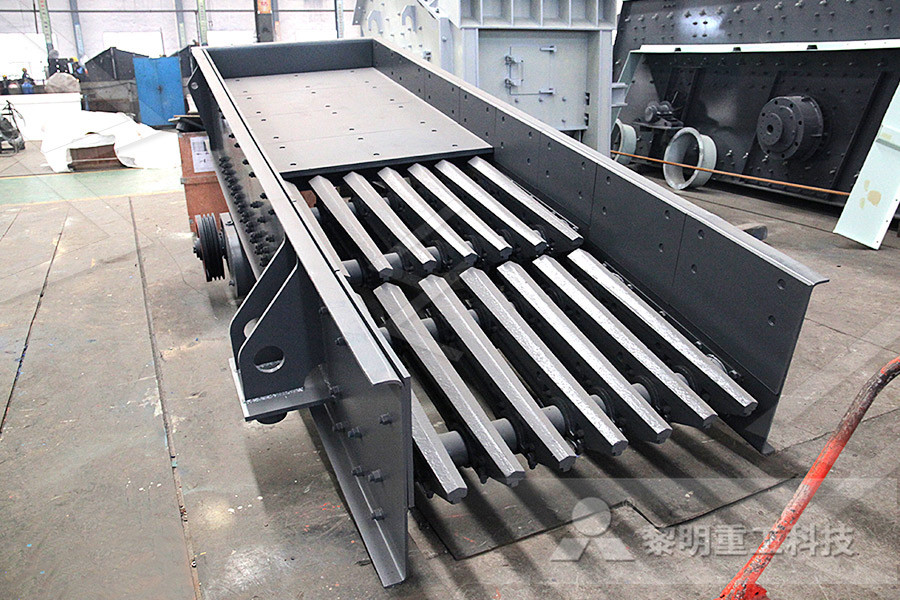

Grey Granite Premiertrak 600E Jaw Crusher ; River Bed Material Warrior 2400 Screen; Limestone and Shale 1150 Maxtrak Cone Crusher ; Mining Overview: Mining; Cast Iron Slag Warrior 800; The Jaw crushers are largescale, heavyduty machinery typically constructed with cast iron and/or steel Often considered a basic machine, jaw crushers have their place in the industry They are often used to reduce rock into nonuniformed gravel To find out more about primary jaw crusher check out our blogTypes of Crushers: What You Need to Know Machinery PartnerThe main parts and main technical parameters of a jaw crusher are presented below 1 Feed Chute 2 Drive Flywheel 3 Vbelts 4 Electric motor 5 Motor Stand 6 Settings and Damping Group 7 Hydraulic What is a Jaw Crusher? – MEKA Crushing Equipment

What are the Materials of the Jaw Crusher Plates

The structure of the jaw crusher is mainly composed of a movable Jaw Crusher Plates, a fixed jaw plate and an eccentric shaft When the eccentric shaft rotates, the movable jaw plate mainly bears the Mar 1, 2023 Jaw crushers for construction materials Jaw crushers for construction materials are an essential tool for the construction industry, as they are used to break down large rocks and stones into smaller, more manageable pieces These machines are commonly used in quarries and mines, where they are used to produce materials such Jaw crushers for final products of construction materialsBreaking jaws for RETSCH's jaw crusher range are available in the following materials: manganese steel stainless steel stainless steel 316L NiHard4 tungsten carbide zirconium oxide The shape of the crushing jaws is determined by curvature and profiling Steel and cast iron Steels are ferrous materials whose carbon content is generally less than 2%Jaw Crushers high quality and reliability from RETSCH

Freedom Series Jaw Crushers McLanahan

McLanahan Freedom Series Jaw Crushers are designed to help producers do even more Often used as the first stage in a crushing circuit, Freedom Series Jaw Crushers can crush even the hardest of materials The attack angle and crushing stroke pattern are engineered to increase capacity up to 15% while minimizing wear on the jaw diesMcLanahan Universal Jaw Crushers are overhead eccentric jaw crushers that continuously reduce material as it passes through the crushing chamber with its aggressive force feed action as the movable jaw compresses inward and downward The sharp primary blow at the top of the chamber reduces material instantly, while a secondary crushing Universal Jaw Crushers McLanahanNov 22, 2021 Jaw crushers include Superior, Type “B” Blake, FineReduction, and Dodge — sizes, 4 by 6 to 84 by 66 inches A reciprocating machine, the crushes material in a straight line between jaws — without grinding or rubbing surfaces are constructed of manganese steel and have corrugated crushing surfaces which reduce the power How does a Rock Crusher Work Jaw Crusher 911Metallurgist

Jaw Crushers

Jaw Crushers jaw crushers are designed to exceed the primary crushing needs of customers in the mining, quarrying, and recycling industries These crushers are amongst the most advanced and reliable in the market and are highly productive in a The Finlay® J960 is the most compact tracked jaw crusher in the ® Finlay range This aggressive and versatile crusher is ideal for small scale onsite crushing of aggregates and construction demolition waste The direct drive jaw chamber is fitted with an unblock feature that maximizes uptime The machine features the robust 900mm Jaw Crushers Heavy Duty FinlayAdvantages of Daswell jaw crushe 1 The structure is simple and firm, and the production is efficient Daswell jaw stone crusher has a relatively firm frame and can work under high pressure The weight of the equipment is about 15% heavier than other manufacturers, and the structure is stronger and more impactresistantJaw Crusher for Hard Materials DASWELL

Jaw Crusher For Sale Jaw Crusher Jaw Crusher Manufacturer

Jaw crusher for sale Production Capacity: 1–1200 t/h Feeding Size: 125–1200 mm Application: pebble, calcite, granite, quartz, concrete, dolomite, bluestone, iron ore, limestone, construction waste, etc Get Price! The jaw crusher is suitable for crushing various ores or rocks with a compressive strength limit below 250 MPa Widely Dec 23, 2020 Mn14Cr2 Jaw Plates Mn14cr2 jaw plates are used in crushing soft stone For example, it has a good life when crushing the easy and nonabrasive blasted rock, nonabrasive gravel, and nonabrasive round rock Mn18Cr2 Jaw Plates Mn18Cr2 is the most popular material for casting jaw crusher jaw platesWhat is the best material for crusher jaw plates?DOVE Jaw Crushers are ideal rock crusher machines, highly efficient and economical for handling Primary and Secondary stone crushing applications of various ores and bulk materials with compressive strength below 320 Jaw Crusher Crushing Plant Hard Rock Mining

What mineral types are good for a jaw crusher?

Feb 16, 2023 Jaw crushers are most commonly used to crush tougher, harder materials such as basalt, granite and quartz However, they can also be used to crush softer minerals such as limestone,Feed material Output size; Jaw crusher: 6:1: 24" 4" Impact crusher: 24:1: 24" 1" Cone crusher: 5:1: 4" 08" Whenever you need a jaw crusher that takes the brunt of the initial reduction in size, impact crushers would not be an option Also if material quality is not an issue, you might want to consider a jaw and cone crusher over an impact Jaw and Cone Crusher Myths Total Operating Costs RUBBLE Feb 17, 2016 jaw crusher production capacity Example capacity calculation of a 10″ x 20″ (250 mm x 500 mm): Pp = 2800 (28 SG) e = 02 (halfway between dolomite and sandstone) If a 60in gyratory Estimate Jaw Crusher Capacity Mineral Processing

Jaw crushers for final products of construction materials

Mar 1, 2023 Jaw crushers for construction materials Jaw crushers for construction materials are an essential tool for the construction industry, as they are used to break down large rocks and stones into smaller, more manageable pieces These machines are commonly used in quarries and mines, where they are used to produce materials such Engineered to be the highestcapacity jaw crusher on the market, the Pioneer ® Jaw Crusher will deliver up to 25 percent more tons per hour than comparable jaw crushersPioneer® Jaw Crushers AstecFeb 15, 2023 There are different jaw plates material in the market, and some of them suits for hard stone while other is not Therefore, you have to choose the right jaw plate for your crusher For example, generally the jaw plate of single toggle jaw crusher is not good at crushing strongly abrasive and hard stone material with large productionThe Most Practical Jaw Crusher Repair and Maintenance Manual

Types of Crushers: What You Need to Know Machinery Partner

Jaw crushers Large amounts of material are fed into the “Vshaped” jaw of this crusher and are reduced using compressive force One side of the V remains stationary while the other side of the V swings against it The material is forced from the wide opening of the V to the narrowest point of the V creating a crushing motion® C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up to 11,000 jaw crusher installations since 1975 Developed to crush the hardest ores and rocks, jaw crushers also perform outstandingly with less demanding materials® C Series™ jaw crushers Outotec