cement raw mill discharge head

2022-06-06T18:06:32+00:00

Raw Mill Feeding Cement Plant Optimization

The feeders are generally 2 to 3 m long and discharge on to a common conveyor which will take feed to mill Feeders for mills meter feed rates and also totalize tons fed For raw Cement vertical mill, also called roller mill, is another raw mill commonly used in cement plants Compared with the cement ball mill, it has a great difference in structure, grinding Raw Mill – Raw Mill In Cement Plant AGICO Cement Raw Low investment: the vertical raw mill set crushing, drying, grinding, grading transportation in one, simple system, compact layout, less space, it also can be arranged in the open air, Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant

Cement Raw Mill Discharge Head activitycampch

2021年12月15日 3 cement raw mix grinding mill remamill system 474 00 64 45 2415 shell and head plates of remamill 70 or remamill 70 hr rubber are highly abrasion beveled Material For Cement Mill Liners Cement Mills internals the cement grinding office material liner raw millas raw and cement mills are composed from 1 to various compartments the cement raw mill discharge head abacplIn raw mill feeding, a system of weighbelts that discharge into the mill feeding device controls the material rate into the millS,Flow Diagram Of Raw Mill In Cement Plant cement raw mill discharge head srdcollegemahur

cement raw mill discharge head tajmahalbelfortfr

Cement Raw Mill Image Cement Raw Mill Image Prompt : Caesar is a famous mining equipment manufacturer wellknown both at home and abroad, major in producing stone cement raw mill discharge head Live chat with our professional customer service! Get the quotation list Chat Now What We Do? We are the world's leading industrial company in cement raw mill discharge head geldermalsenwebonlineTube Mill Internals, Shell Liners for Cement Mills AIA Engineering Vertical Roller Mill for Cement Raw Material – Mining: Capacity: 21210 t/h: Motor Power: kW: cement raw mill discharge head

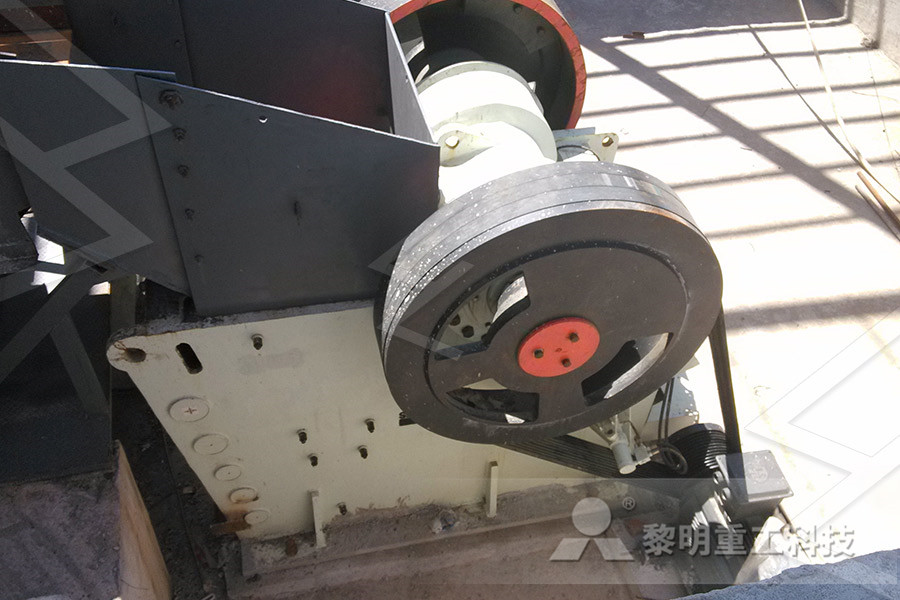

Cement Raw Mill in Cement Plant for Cement Raw Meal

Raw mill is mainly used for grinding cement raw meal in the cement factory production process It is also suitable for metallurgical, chemical, electric power and other industrial mining enterprises to grind various ores and other grindable materials Cement raw meal is a mixture of various raw materials before cement calcinationThe cement mill can be used as a raw mill or cement grinding mill, AGICO Cement provides vertical cement mill, cement ball mill and other highquality cement grinding machines for you! Skip to content +86 s about blog contact EN ES about blog contact MenuCement Mill Cement Ball Mill Vertical Cement Mill AGICORawmill Wikipedia A rawmill is the equipment used to grind raw materials into "rawmix" during the manufacture of cementRawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement millThe rawmilling stage of the process effectively defines the chemistry (and therefore physical properties) of the cement raw mill discharge head crawlsquadafrica

Cement Raw Meal Homogenization Process in The

Cement Mill Separator; Cement Mill; Others Menu Toggle Conveying System; Overland Conveyor; many multimaterial flow silos are also equipped with discharge silos with different volumes, so that the raw meal homogenized by funnel flow and radial mixing flow in the silo can be discharged into the warehouse or the silo under the main silo The feeders are generally 2 to 3 m long and discharge on to a common conveyor which will take feed to mill Feeders for mills meter feed rates and also totalize tons fed For raw mill feeding, table feeders, belt feeders, and weigh feeders have been used However, weigh feeders are the most commonly preferred feeders for limestone, clay and Raw Mill Feeding Cement Plant OptimizationIn raw mill feeding, a system of weighbelts that discharge into the mill feeding device controls the material rate into the millS,Flow Diagram Of Raw Mill In Cement Plant diagram cement mill pdsasacozaFlow flow diagram of raw mill and kiln esp system A schematic diagram of the raw mill system in a cement plant is illustrated in Fig 1 In this cement raw mill discharge head srdcollegemahur

Cement Finish Milling (Part 1: Introduction History)

2019年12月2日 Size reduction is a critical process at numerous stages of cement manufacture mainly to ensure homogeneity and reactivity of the cement, raw mix, and fuels The finish mill system in cement 2016年1月20日 In the surveyed cement plant, three balances are established between input and output material in the raw mill, clinker production, and cement grinding system 248 t, 469 t, and 341 t of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding stages; waste gases Analysis of material flow and consumption in cement2012年6月1日 The raw mill operates for about 7200 h in a year The amount of carbon dioxide emission per kWh of energy consumption can be taken as 062 kg [22] 6 kWh and the corresponding carbon dioxide emission is about 18,592 tons a year The CO 2 emission is reduced to 17,817 tons after the reduction of moisture content; and it is reduced to Reducing energy consumption of a raw mill in cement

Cement Manufacturing International Finance Corporation

When the raw materials have high alkali or chloride content, a portion of the collected dust must be disposed of as solid waste, to avoid alkali buildup Leaching of the dust to remove the alkali is rarely practiced Grinding mill operations also result in particulate emissions Other materialshandling operations, such as conveyors, reCoal mill is the main equipment in the pulverized coal preparation processBecause calcining topgrade cement clinker requires a stable supply of coal powder as the fuel of cement kiln, and more than 85% of pulverized coal should be finer than 200 mesh, water content less than 2%, and calorific value more than 6000Kcal/kg, therefore the pulverized coal Cement Mill Cement Grinding Machine AGICO Cement Ball mills for cement raw material and coal equipped with a drying compartment adequately air swept with hot gas (2535M/sec above the ball charge), can handle moisture about 8% Fully air swept mills (56M/sec) can dry up to 1214% moisture In case of bucket elevator mills (gravity discharge mills), ground material is taken by Raw Material DryingGrinding Cement Plant Optimization

Volume 3, Issue 5, November 2013 Study of Processing

2014年1月14日 A raw mill is the equipment used to grind raw materials into “raw mix" during the manufacture of cement Dry raw mills are the normal technology installed today, allowing minimization of energy consumption and CO2 emissions Process of raw mill in grinding of raw material and silo storage 1 Transporting crushed raw material to raw millContribute to chengxinjia/ development by creating an account on GitHub/ discharge head mill pdfmd at main Mechanical engineer with more than 10 years of solid experience in construction of Industrial plant (Cement Mark Joseph Samson Project

Reza Yudhistira Production Operator PT Semen Jawa

After that, I moved to a cement company in western Java, PT Semen Jawa (SCG) There, I work as a raw mill production operator I operate Raw Mill and its supporting equipment such as separator, belt conveyor, bucket elevator, and others in CCR I have also received training to be a coal mill operator, and I can control the coal mill wellcement raw mill discharge head Live chat with our professional customer service! Get the quotation list Chat Now What We Do? We are the world's leading industrial company in the mining and aggregates industries and in the flow control business China Grinding Mill is quite experienced in construction, milling and mining industrycement raw mill discharge head geldermalsenwebonline