working principle of a roller crusher

2023-06-27T07:06:36+00:00

Roll Crusher an overview ScienceDirect Topics

The capacity of the singleroll crushers is a function of the roll gap, the roll length, and the speed, and ranges from about 30 tons/h (27 metric tons/h) for a 24inchlong (61 cm) roll crushing to ¾ inch (2 cm), up to approximately 1500 tons/h (1360 metric tons/h) for an 84 2021年8月20日 Roll crusher working principle structure Roll crusher working principle structure +86371 [ protected] NO 2, Qinling Road, The working Roll crusher working principle Henan Deya Machinery 2022年1月7日 The roll crusher working principle is a physics of angular relations When the material is too large to pass the rollers, it will not be crushed into a small particle In this BTMAWhat is the principle of a roller crusher? BTMA

The working principle and performance advantages of

2022年9月26日 Working principle of double roller crusher 1 This series of roller crushers are mainly composed of rollers, roller support bearings, pressing and adjusting devices, 2012年7月30日 Double Roller Crusher Working Principle 2 roller; Material; Stationary bearing seat; Movable bearing seat; Spring; Base frame; Smoothsurfaced rolls are Double Roll Crusher Henan Deya Machinery Co, Ltd2022年7月7日 Principle of the Roll Crusher Roll Crushers are compression type crushers, and were once widely used in mining They have, within the last 10 or so years, fallen Roll Crushers SolidsWiki

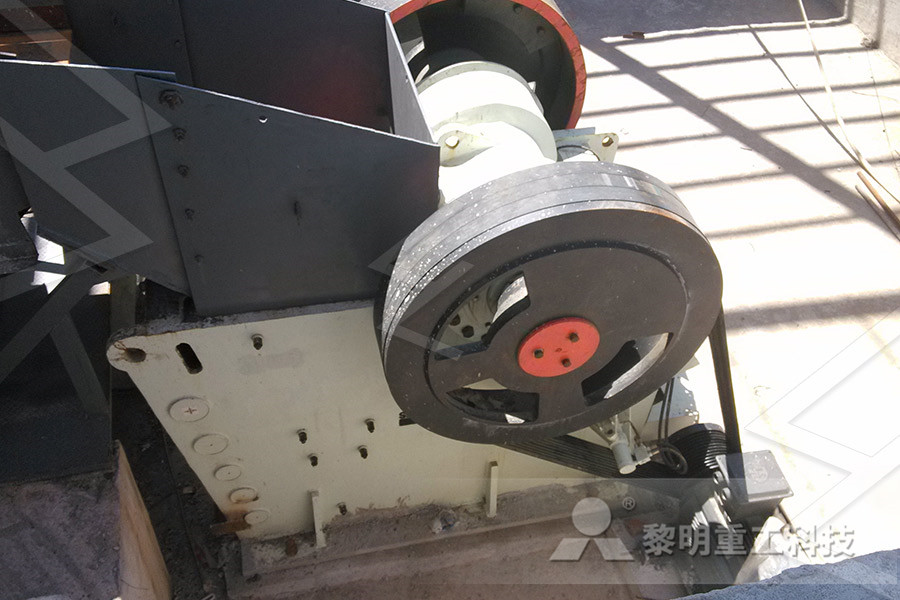

Roller Crusher Single/Double Roll

Roller crusher is a very old crushing equipment that appeared in 1806, and its structure is simple It can crushers iron ore, Quartz Stone, rock gold, rock tantalum niobium 2022年7月19日 The characteristics of this kind of roll crusher is two rollers of the same diameter, rotational speed, moveable roller higher than the fixed one Two roller rotation The Working Principle of Roll CrusherWorking principle of roller crusher 1 The pair of roller crusher (counterroller) is mainly composed of roller assembly, roller support bearing, pressing and adjusting device and Advanced Machinery Manufacture Co, Limited

The roller crusher working principle and matters Detailed

2017年12月12日 The working principle: The roll crusher will be broken material feeding the mouth fall between two rollers, extrusion, finished product material nature When the Working principle of gyratory crusher for breaking lumpy ore pressed between a fixed jaw and rotating conical head 13312 Secondary Crusher The falling feed material is squeezed and crushed between the rollers The final product passes through the discharge point This type of crusher is used in secondary or tertiary crushing applicationsCrusher an overview ScienceDirect Topics2012年7月30日 Double Roller Crusher Working Principle 2 roller; Material; Stationary bearing seat; Movable bearing seat; Spring; Base frame; Smoothsurfaced rolls are usually used for fine crushing, whereas coarse crushing is often performed in rolls having corrugated surfaces, or with stub teeth arranged to present a chequered surface patternDouble Roll Crusher Henan Deya Machinery Co, Ltd

Types of Crushers: What You Need to Know Machinery

Roller crushers A roller crusher reduces material by compressing it between two turning cylinders, parallel to each other The cylinders are mounted horizontally with one resting on strong springs and the other framed permanently Impact crushers have a very similar working principle except instead of the rotating parts hitting the 2023年3月1日 Working principle of roll crusher The main working parts of the roller crusher is the cylindrical rollers The rollers are supported by the fixed and movable bearings, and they are relatively rotating which are Roll Crusher With stable Performance Fote 2022年2月10日 The working principle of the roller crusher is that two sets of separately driven roller shafts crush the material by the squeezing force and grinding shear force generated by the relative rotation When the material enters the crushing cavity of the machine, the material is subjected to the meshing force of the rotating roller, so that the What’s a DoubleRoller Crusher? Eastman Rock Crusher

Advanced Machinery Manufacture Co, Limited

Working principle of roller crusher 1 The pair of roller crusher (counterroller) is mainly composed of roller assembly, roller support bearing, pressing and adjusting device and driving device The two rollers are respectively fixed on the two rotating shafts with keys, each end of the shaft is supported by a set of bearings, the fixed wheel Crusher Working Principle The primary gyratory crusher breaks the material by feeding mouth into the two rollers between the extrusion crushing, finished materials naturally fall In case of too hard or can not be broken, Gyratory Crusher l Introduce, Working Principle2016年10月13日 Therefore, the traditional roller crusher are used longtooth gear drive, which can change the center of the two rollers in the operation without breaking the tooth characteristics The working surface of the roller, depending on the requirements of the use, you can use smooth or tooth surface or slottype surfaceThe working principle of the gangue to roll crusher in

Hydraulic Roller Press in Cement Plants AGICO Cement

Hydraulic Roller Press Designed Capacity: 290 ~ 1580 TPD Customized Design: Support Condition: Brand new Roller Width: 800 ~ 1600 mm Application: crushing and pregrinding of limestone, coal, clinker, etc CHAT NOW SEND INQUIRY The cement roller press is a type of materialcrushing machine which is often used in cement plantsDownload scientific diagram Working principle of the M and S rollers from publication: A cement Vertical Roller Mill modeling based on the number of breakages This study investigated a Working principle of the M and S rollers Download 2021年8月10日 The working principle structure of Double roll crusher is as follows: 1 the series of roll crusher is mainly composed of the roller, the roller support bearings, compaction and adjusting device and driving unit and other parts 2, the adjustment of the discharging granularity: with a wedge or gasket between the two roller adjustment device How about Working Principle Structure of Roller Crusher

Roll Crusher With stable Performance Fote

2023年3月1日 Working principle of roll crusher The main working parts of the roller crusher is the cylindrical rollers The rollers are supported by the fixed and movable bearings, and they are relatively rotating which are Getting started; roller crusher working principle; roller crusher working principle China Manufacturers, Factory, Suppliers Our firm sticks on the theory of "Quality will be the life in the enterprise, and status could be the soul of it" for roller crusher working principle, LargeScale Mining Separator, Mining Elevators For Sales, String Sieve Plate,Featured Productsroller crusher working principle Hnjinte2021年2月5日 The Type of Roll Crusher The working principle of toothed roll crusher: Doubletoothed roll crusher is composed of a pair of rotating toothed roller Singletoothed crusher is composed of one rotating toothed roller and one curved crushing plate The tooth on the roller surface can bite the coal and crush, in this way, the crushed material The Type of Roll Crusher China Crusher Mesto, Sandvik,

Working Principle Of Smooth Roll Crushers Stone

2017年10月25日 Working Principle of Roll Crusher: These roll crusher are made using a pair of smooth rollers, made of cast steel, running in opposite directions, Click Chat Now working principle of roll crusher [ crusher and mill] ( Roll crushers used for minerals and metal ores have smooth faced rolls )working principle of a roller crusher longwaydown Jaw Crusher Working PrincipleA sectional view of the singletoggle type of jaw crusher is shown belowIn one respect,the working principle and appliion of this machine is similar to the Dodge crushers the movable jaw has its maximum movement at the top of the crushing chamber,and minimum en/working principle of smooth roll crushermd at mainFourroll Crusher Working Principle Fourroll crusher can be divided into two crushing stages from top to bottom When working, motors will drive the belt pulleys on both sides of the crusher to rotate the two pairs of rollers Rollers of the same stage run in the opposite direction and mesh with each other When materials enter the crusher Fourroll Crusher Roll Crusher AGICO Roller Crusher

Roller Mill Working Principle Liming Heavy

Roller Mill Working Principle Author:liming Post Date: Roller Mill Introduction: High Pressure Suspension Roller Mill is my chief engineer Mr Bai Yinghui, wearable device experts on the basis of the experience of 2023年1月6日 A double toothed crusher with less volume is composed of two toothed rollers which is installed in parallel and rotates in opposite directions The twotoothed rollers adopt nonmeshing and nonconstant Reliable Toothed Roll Crusher Fote MachineryDownload scientific diagram Working principle of the M and S rollers from publication: A cement Vertical Roller Mill modeling based on the number of breakages This study investigated a Working principle of the M and S rollers ResearchGate