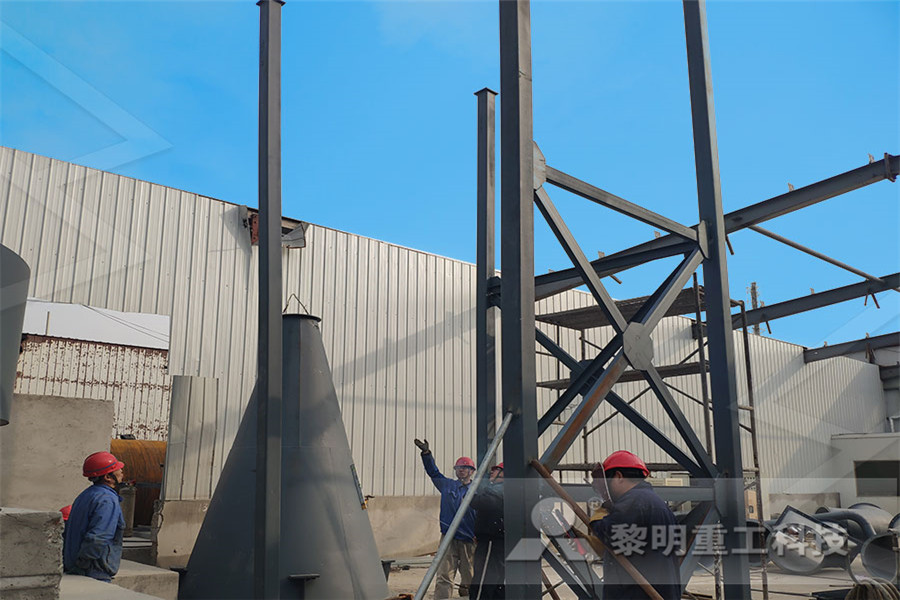

installation for vertical grinding mill

2022-04-24T15:04:29+00:00

VERTIMILL Vertical Grinding Mill YouTube

Nov 6, 2013 VERTIMILL Vertical Grinding Mill Outotec 209K subscribers Subscribe 104 40K views 9 years ago 's VERTIMILL Vertical Grinding Mill can Lower capital cost 50% less footprint compared to ball mill Lower operating cost 40% higher energy efficiency Versatile applications Capable of handling multiple feed sizes up to 6 mm and grinding to products less Vertimill® OutotecThe Raymond® Vertical Mill is a highspeed air swept swing hammer mill used to pulverize materials in the extreme fineness range The principle of integral air classification, The Raymond® Vertical Mill Schenck Process

HIGmill high intensity grinding mill Outotec

A compact, simple installation and process HIGmill™ has a less complex and more compact process layout and flow sheet than other stirred media mills The process comprises just a scalping cyclone with no circulating The Atlas roller mill by NETZSCH Ecutec is the solution for the fine grinding and classification of a wide variety of materials including: Calcium Carbonate, Dolomite, Talc, Atlas Vertical Roller Mill NETZSCH Grinding DispersingThere is a large gap between the tip speed and power intensity of the lowspeed vertical mills and the highspeed horizontal mills The VXP mill bridges the gap between highspeed and lowspeed mills The VXPmills VXPmill for fine ultra fine grinding

Ball Mill Maintenance Installation Procedure

Oct 19, 2016 It has been found that concrete foundations on a weight basis should be at least 1½ times the total weight of the grinding mill with its grinding media Allowable bearing pressure between concrete Jun 24, 2022 The vertical grinding mill is installed vertically, with less system equipment, compact structure, small footprint, short cycle, convenient installation and low How to choose between ball mill and vertical roller mill?Here is a list of some of our equipment: DMG MORI BY TAIYO KOKI (VERTICAL MATE 85 MULTIPROCESS GRINDING MACHINE) PD32 OD Grinder RD23 OD Grinder (2) RC32 OD Grinder (Straight Head) RD32 OD Grinder Okamoto PRGDX Series Cincinnati Milacron 2EF700 ID OD Grinder (2)Grindal Company OD ID Precision Grinding Specialists Since

The Raymond® Vertical Mill Schenck Process

The Raymond® Vertical Mill is a highspeed air swept swing hammer mill used to pulverize materials in the extreme fineness range The principle of integral air classification, originally developed by Raymond® , has been applied with outstanding success to this mill As a result, a large number of products can be reduced to 95% to 99% passing Jun 14, 2019 How Vertical Grinding Mills Work (Coal Pulverizer Example) saVRee 192K subscribers Join Subscribe 1K Share 58K views 3 years ago Industrial Engineering Want to continue learning How Vertical Grinding Mills Work (Coal Pulverizer Example)The Atlas roller mill by NETZSCH Ecutec is the solution for the fine grinding and classification of a wide variety of materials including: Calcium Carbonate, Dolomite, Talc, Bentonite, Barites, Petroleum Coke, Calcium Oxide (Burnt Atlas Vertical Roller Mill NETZSCH Grinding Dispersing

Vertical roller raw mill capacity upgrade

downtime during installation Downtime can be further minimised by installing the upgrade during a planned maintenance stop Typically, it takes only a few days to connect the HRP to the mill High level of flexibility Use the HRP with the vertical mill when extra capacity is needed, and run the mill without the HRP when it’s not ShouldAnswer: Vertical roller mill is a collection of material crushing and grinding of large grinding equipment, it can be widely used in cement, silicate, building material, refractory material, all kinds of metal and nonmetallic minerals, glass, ceramics and other manufacturing industries VerticaWhat are the right installation methods for a vertical roller mill?Oct 19, 2016 It has been found that concrete foundations on a weight basis should be at least 1½ times the total weight of the grinding mill with its grinding media Allowable bearing pressure between concrete Ball Mill Maintenance Installation Procedure

How to choose between ball mill and vertical roller mill?

Jun 24, 2022 The vertical grinding mill is installed vertically, with less system equipment, compact structure, small footprint, short cycle, convenient installation and low construction cost 2 Process flow CLUM vertical roller mill integrates crushing, grinding, drying and grading, with simple process, compact structure and low operating costMar 6, 2023 Vertical roller mills are typically used for dry grinding, which may not be suitable for the highmoisture content of iron ore Wear and tear: Iron ore is a hard and abrasive material thatWhy is vertical roller millbased dry grinding not used in iron ore Vertical raw mill working – CGM Grinding Plant Vertical Raw Mill Cement Industry,Vertical Mill Type 1high performance mill 2easy to install in work site Rod Mill For Sale / Raw Mill / Raw Ball Mill How To Install Vertical Raw Mill Crusher Mills, Cone Crusher,

Modular grinding plant Mill system ready2grind

Installation procedure Client has prepared the site Starting Growing Nearly ready Decoration and small issues End of installation procedure after 2 months Grinding on the ready2grind system The ready2grind system is Answer (1 of 2): This is from a simple Google search Heavy duty machinery for grinding down stuff Vertical Roller Mill (60045μm) Vertical Roller Mill is our newlylaunched product which is applied as a solution to the technical issues such as low output and high energy consumption in the ordWhat is the installation of vertical roller mill installation?Guilin Hongcheng's large vertical grinding mill is being installed in orderHLM1100 Vertical Roller Mill With High Output, Small Land Area Required: mkt@Guilin Hongcheng's large vertical grinding mill is being installed

Vertical Stirred Mill Mineral Processing Equipment CITIC HIC

Industry Leading Company of Vertical Stirred Mills For over 60 years of experience in the mineral processing industry, CITIC Heavy Industries (CITIC HIC) has been always committed to increase the grinding efficiency of minerals by constantly searching for ways to improve and develop energysaving highefficiency ore grinding equipmentA vertical leap in fine grinding, the FTM reduces energy consumption and maximises productivity Simple, modular component structure allows rapid installation ; ® Tower Mill A vertical leap in fine grinding English PDF (3030KB) Download Keep exploring Stories from News 10 February 2023 ® Tower MillInstallation procedure Client has prepared the site Starting Growing Nearly ready Decoration and small issues End of installation procedure after 2 months Grinding on the ready2grind system The Modular grinding plant Mill system ready2grind

Vertical Stirred Mill Mineral Processing Equipment CITIC HIC

Our vertical stirred mill can be configured with helical path unit, jacking system, spiral conveyor, hydraulic wrench, grinding media adding unit, etc Control PLC system is adopted to achieve lowpressure control and system protectionOct 19, 2016 On Mill Installation and Maintenance Grinding Mill FOUNDATION Establish vertical and horizontal centerline of mill and pinion shaft against the effects of this, we recommend that the Ball Mill Maintenance Installation ProcedureWhat is the installation of vertical roller mill installation? Put the base of the transmission device into the pit and maintain a suitable height Use a level to correct the upper plane "A" and fix the boltsWhat are the right installation methods for a vertical roller mill?

Why is vertical roller millbased dry grinding not used in iron ore

Mar 6, 2023 Vertical roller mills are typically used for dry grinding, which may not be suitable for the highmoisture content of iron ore Wear and tear: Iron ore is a hard and abrasive material thatMillstone is one of the key parts of vertical mill, which is mainly composed of resistance ring, liner and baseOptimize the design of the grinding disc casting process to overcome the deficiencies of the previous structure, make the grinding disc base uniformly stressed, increase the bite angle between the grinding disc grinding rollers, and avoid brush Vertical Roller Grinding Machine Roller AssemblyVertical raw mill working – CGM Grinding Plant Vertical Raw Mill Cement Industry,Vertical Mill Type 1high performance mill 2easy to install in work site Rod Mill For Sale / Raw Mill / Raw Ball Mill How To Install Vertical Raw Mill Crusher Mills, Cone Crusher,

Guilin Hongcheng's large vertical grinding mill is being installed

Guilin Hongcheng's large vertical grinding mill is being installed in orderHLM1100 Vertical Roller Mill With High Output, Small Land Area Required: mkt@The roller of the vertical grinding mill is placed on the grinding table like a car wheel and is connected to a rocker arm When the vertical grinding mill is running, the position of the grinding roller is unchanged Grinding rollers do autobiographical movement without direct contact with the grinding tableVertical Roller Mill Manufacturers Provide High Quality ServiceIntegrated Vertical Coal Mill Grinding Equipment Energy Efficient Drying Pulverized Coal Vertical Mill Production Line Explosion Proof 90t/H Environmentally Friendly Coal Powder Vertical Roller Mill Large Capacity Large Capacity 28 T / H Pulverized Vertical Coal Mill Production Line HVM1700Quality Vertical Coal Mill Limestone Vertical Mill factory from

Analysis of installation and maintenance of vertical roller mill

Generally, the vertical roller mill should replace the bearing oil when it is running for 3 000 h After replacing the new lubricant, it is required to check the quality of the oil every two months to see if there is any impurity and whether the oil is contaminated The grinding roller oil level is checked once a month