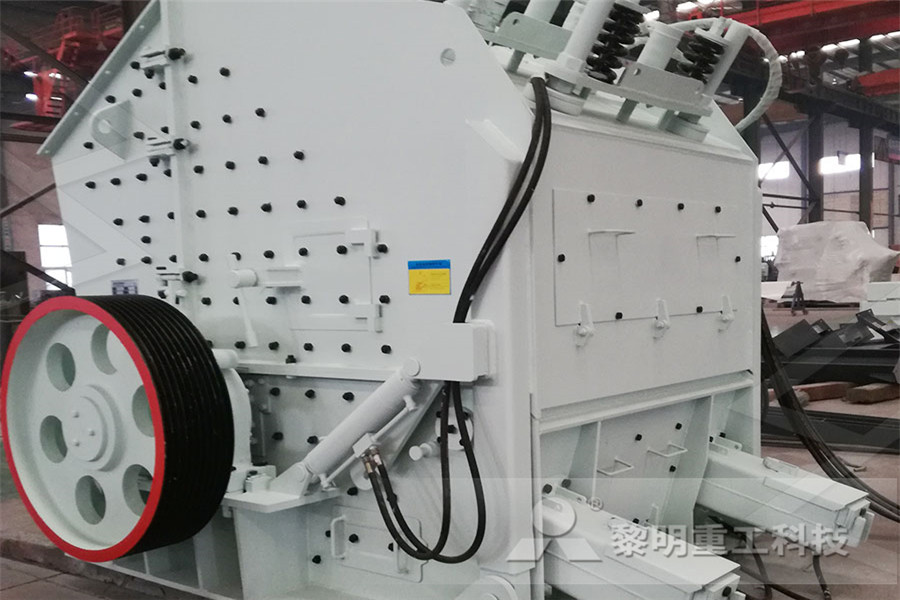

the diagram of jaw crushing machine

2021-11-26T22:11:55+00:00

Jaw Crusher Components Parts Mineral Processing Metallurgy

Jul 24, 2015 Jaw Crusher Components Parts Although the jaws do the work, the real heart of the jaw crusher and its components are the Jun 8, 2022 A fixed jaw, mounted in a Vshaped alignment, is the stationary breaking surface, while a movable, “swing” jaw exerts force on How Does a Jaw Crusher Work Jaw Crusher Kemper Jaw Crushers are a compressiontype machine that crush material between a moving piece of steel and a stationary piece of steel They are used for primary and sometimes Jaw Crushers McLanahan

Industrial Solutions Jaw crushers ThyssenKrupp

The singletoggle jaw crusher with the largest antifriction flywheel energy 1) with new crushing elements 2) 1,200 rpm possible All data are intended as a guide only The A jaw crusher consists of two jaws, one of which is movable, while the other is fixed Jaw crushers are mainly used to break the elements that are approximately 15 m to 24 m in Jaw Crusher Working Principle – StudiousGuyThe main parts and main technical parameters of a jaw crusher are presented below 1 Feed Chute 2 Drive Flywheel 3 Vbelts 4 Electric motor 5 Motor Stand 6 Settings and Damping Group 7 Hydraulic What is a Jaw Crusher? – MEKA Crushing Equipment

How to Design a Jaw Crusher Metallurgist Mineral

How to Design a Jaw Crusher Metallurgist Mineral Processing EngineerThe material is forced from the wide opening of the V to the narrowest point of the V creating a crushing motion Jaw crushers are largescale, heavyduty machinery typically Types of Crushers: What You Need to Know Machinery PartnerDownload scientific diagram KINEMATIC DIAGRAM OF THE JAW CRUSHER [16] from publication: Machine Learning Technics for Remaining useful Life Prediction using KINEMATIC DIAGRAM OF THE JAW CRUSHER [16]

In depth – Components of a Jaw Crusher PROPEL INDUSTRIES

Jun 14, 2021 A jaw crusher consists of Crusher Body Pitman Jaw plate Rear end frame Eccentric shaft Flywheel Jaw crusher bearings Toggle plant Retraction spring and screw rod Check plate Setting adjustment 1 Crusher Body The design of the crushing body ensures that it is capable of exhibiting resistant to bending stress even when the All jaw crushers reduce large sized rocks, ore, or other material by a compression action A fixed jaw, mounted in a Vshaped alignment, is the stationary breaking surface, How Does a Jaw Crusher Work Jaw Jul 24, 2015 Jaw Crusher Components Parts Although the jaws do the work, the real heart of the jaw crusher and its components are the toggle plates, the pitman, and the Jaw Crusher Components Parts Mineral

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE

and fines; hence, the machine tends to serve more like a pulverizer Figure 3 illustrates the angle of nip in a jaw crusher Figure 3: Angle of nip in a jaw crusher 23 Crusher Jaw Plates Compression of materials undergoing crushing in a jaw crusher is achieved when the movable jaw presses the feed against a stationary jawThe material is forced from the wide opening of the V to the narrowest point of the V creating a crushing motion Jaw crushers are largescale, heavyduty machinery typically constructed with cast iron and/or steel Often considered a basic machine, jaw crushers have their place in the industryTypes of Crushers: What You Need to Know Machinery PartnerMar 10, 2016 Crushing Plant Flowsheet DesignLayout In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet Crushing Plant Flowsheet Design

Characteristics and Comparison of Four

Feb 15, 2023 The swing jaw plate hangs on the eccentric drive shaft and moves up and down in elliptical motion, which compresses rock material as it moves down from the Jaw crusher, invented by Whitney Blake in 1858, is a primary stone crushing machine for reducing minerals or stones into smaller sizes It is a musthave machine in Jaw Crusher for Primary Crushing Fote A laboratory Blake type Jaw crusher ( Figure 1 ), with an opening of 10 Â 12 cm and a jaw length of 315 cm, was used in the experiments Three different size fractions ( À View of Jaw crusher using in experiments

Simple Diagram For Crusher Crusher Mills, Cone Crusher, Jaw

Crusher – Wikipedia, the free encyclopedia A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust Crushers may be used to reduce the size, or change the form, of waste ROCK CRUSHER OPERATING INSTRUCTIONS Models RC46 RC46T INTRODUCTION: The new RC46 Rock Crusher is a three stage crushing machine that can reduce a rock as large as 4 x 6 inches into powder in moments The first stage is a jaw crusher, that initially crushes the rock to a size of approximately 1/4 of an inchModels RC46 RC46T Keene EngThe diagram also indicates that the calculations drop to within the installed plant data for values of S C below 10 Most other calculation methods tend to estimate higher throughputs than the manufacturers recommend; hence, the crusher manufacturers should always be consulted For example, rock destruction by a boring machine, a jaw or Jaw Crusher an overview ScienceDirect Topics

Gyratory Crusher Functional Diagram Crusher Mills, Cone Crusher, Jaw

Figure 22 Functional diagram for Jaw Crusher 72 Figure 24 Functional diagram for Omnicone Gyratory Cone Crusher 77 Figure 25 Functional diagram for liming VSI 80 diagram of crushing machine in geology blast furnace diagram – stone crusher machine equipments Structure and function of the lungs Fig 1 shows a sectional view of Our portable jaw crushing plants represent the very latest in jaw crusher technology Engineered to be the highest capacity jaw crusher on the market, our plants can deliver up to 25% more tons per hour than other comparable plantsPortable Jaw Plants AstecJun 14, 2021 A jaw crusher consists of Crusher Body Pitman Jaw plate Rear end frame Eccentric shaft Flywheel Jaw crusher bearings Toggle plant Retraction spring and screw rod Check plate Setting adjustment 1 Crusher Body The design of the crushing body ensures that it is capable of exhibiting resistant to bending stress even when the In depth – Components of a Jaw Crusher PROPEL INDUSTRIES

Jaw Crusher an overview ScienceDirect Topics

The mechanism of movement of rocks down the crusher chamber determines the capacity of jaw crushers The movement can be visualised as a succession of wedges (jaw angles) that reduce the size of particles progressively by compression until the smaller particles pass through the crusher in a continuous processionand fines; hence, the machine tends to serve more like a pulverizer Figure 3 illustrates the angle of nip in a jaw crusher Figure 3: Angle of nip in a jaw crusher 23 Crusher Jaw Plates Compression of materials undergoing crushing in a jaw crusher is achieved when the movable jaw presses the feed against a stationary jawDESIGN AND OPERATIONS CHALLENGES OF A SINGLE ROCK CRUSHER OPERATING INSTRUCTIONS Models RC46 RC46T INTRODUCTION: The new RC46 Rock Crusher is a three stage crushing machine that can reduce a rock as large as 4 x 6 inches into powder in moments The first stage is a jaw crusher, that initially crushes the rock to a size of approximately 1/4 of an inchModels RC46 RC46T Keene Eng

Crushing Plant Flowsheet DesignLayout Mineral

Mar 10, 2016 Crushing Plant Flowsheet DesignLayout In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be Feb 15, 2023 The swing jaw plate hangs on the eccentric drive shaft and moves up and down in elliptical motion, which compresses rock material as it moves down from the feeding part Double toggle jaw crusher Also, Characteristics and Comparison of Four Types of The crushing efficiency of the jaw crusher is quite high and the crushing ratio is 36 Structural diagram The main parts and usage of jaw crusher We all know that jaw plate is the most easily worn parts among various Jaw Crusher for Primary Crushing Fote Machinery

View of Jaw crusher using in experiments

A laboratory Blake type Jaw crusher ( Figure 1 ), with an opening of 10 Â 12 cm and a jaw length of 315 cm, was used in the experiments Three different size fractions ( À 90 þ 50 mm, À 50 þ Flow Diagram For Mobile Coal Crusher Manganese Crusher Crusher Jaw Mobile simple small stone crusher schematic July 4, 2012, Comments Offliming Manufacturer of Stone Crusher, Jaw Crusher, Mobile Crusher, Ball Mill, and Mobile Jaw Crusher SchematicsCrusher – Wikipedia, the free encyclopedia A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust Crushers may be used to reduce the size, or change the form, of waste Simple Diagram For Crusher Crusher Mills, Cone Crusher, Jaw

Jaw Crushers

jaw crushers are designed to exceed the primary crushing needs of customers in the mining, quarrying, and recycling industries These crushers are amongst the most advanced and reliable in the market and are highly productive in a variety of applications Jaw crushers are typically used as primary crushers because they can take Jun 30, 2017 The outcome of the result was used to redesign and develop a prototype crushing machine with better output crushing pressure of 131×10⁵ kN/m² and capable of crushing 425–569 kg of rock per (PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 44)A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure 44(a)) and it is the most widely used in primary crushing stages (Behera et al, 2014)Impact Crusher an overview ScienceDirect Topics

Why fine material should not enter a jaw crusher?

Mar 8, 2023 Fine materials should not enter a jaw crusher because they tend to cause damage to the machine over time due to the small size and abrasive nature of the material They can also clog or jam the